Jack Up Floating Floor Isolation Mounts

Mason Industries are the global leaders in providing engineered solutions for the isolation of pipe and ductwork.

We can provide take off services for identifying location and quantity of vibration isolation hangers for plant room and risers.

Our engineers can advise on thermal expansion, riser design and vibration isolation support systems for pipe and ductwork.

For more complicated rise designs we will issue an engineered layout noting sizing and location of isolation mounts within the riser.

Mason Mercer does not charge for this service and is offered on any project where we provide an isolation hanger for.

Please see our full catalogue of isolation hangers below

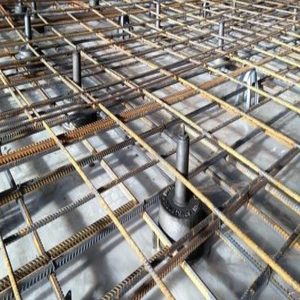

It has been proven that the most fool-proof and safest way to establish the air gap is the jack-up or lift-slab method. The FSN system ensures there is no bridging of the two elements due to slurry ingress.

Plastic sheeting is placed on the sub-floor as a breaker layer, isolators are placed on the plastic sheeting, reinforcing steel or mesh rests on the isolator housings and the concrete floor is poured. After the concrete has cured, the slab is lifted to elevation by turning adjustment bolts above each isolator to any specified air gap between 25mm -100mm.

The Mason FSN Jack Up floor system does not need to be jacked into position immediately. It can be left sitting on the structural slab enabling upper floor props to be installed and formwork cycle to continue for floors above.

All of the Mason FSN Jack Up Floor rubber mounts have a 3X overload built in to enable heavy equipment to be rolled over the slab into position.

Applications – Seismic & Non-Seismic

- Rooftop Sports Courts

- Generator Plant Rooms

- Mechanical Plant Rooms

- Gymnasiums

- Operating Suites

- Theatres

- Loading Docks

Capacity

- 152kg – 1588kg per mount

Slab Thickness

- 75mm – 300mm

Deflection

- 5mm – 8mm

Options

- Seismic Snubber (SFFS)

- Floor Drain (CFD)

Specification

Bell shaped castings with integral lugs to locate reinforcing, shrouding 50mm thick LDS isolators moulded to the following and all other AASHTO bridge bearing specifications. All housings shall have (20mm) minimum diameter jackscrews. Deflections shall not exceed 8mm nor the frequency 9 Hz. Isolators shall be Mason Industries type FSN.

Situations arise where there is a requirement for a lower natural frequency in the floating floor elements that what can be achieved by a rubber isolator.

We have engineered purpose build jack up isolators which house springs. The springs are installed once the concrete is poured. The slab is jacked into position in the same manner our our FSN type jack up isolators.

Plastic sheeting is placed on the sub-floor as a breaker layer, isolators are placed on the plastic sheeting, reinforcing steel or mesh rests on the isolator housings and the concrete floor is poured. After the concrete has cured, the slab is lifted to elevation by turning adjustment bolts above each isolator to any specified air gap between 25mm -100mm

Applications – Seismic & Non-Seismic

- Rooftop Sports Courts

- Bowling Alleys

- Free Weight Gymnasium Areas

- Aerobic Rooms

- Powerlifting areas

- Treadmills

Capacity

- 204kg – 1331kg per mount

Slab Thickness

- 75mm – 300mm

Deflection

- 25mm – 50mm

Options

- Seismic Snubber (SFFS)

- Floor Drain (CFD)

Specification

Cylindrical shaped castings with integral lugs to locate reinforcing, shrouding 25-50mm deflection spring isolators. All housings shall have threaded compression plates and a neoprene cup to the base of the spring. Isolators shall be Mason Industries type FS.